Title: PE Protective Film Solutions for Optoelectronics: Surface Protection for BLU/Optical Sheets/Plates

Keywords: PE Protective Film, Optoelectronics Industry, BLU Protection, Optical Sheet Protection, Temporary Surface Protection

Introduction

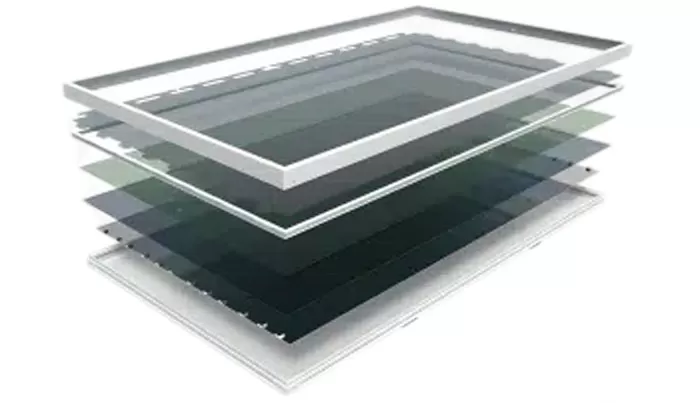

In optoelectronic manufacturing, surface protection is vital to ensure product quality. As a specialized provider, we deliver PE protective films, including advanced self adhering film solutions, for BLU (Backlight Units), mobile covers, touch panels, and optical plates, offering scratch resistance, moisture barrier, and contamination prevention during production and logistics.

1. PE Film in BLU Manufacturing Process

BLU components require full-process protection for optical films (e.g., diffusion films, prism sheets):

– Scratch & Impact Resistance: Low-tack PE films with >90% transparency protect delicate surfaces.

– Thin-Film Coating Protection: Isolate particles during vacuum deposition to ensure coating uniformity.

– Thermal Stability: Withstand up to 120°C in processing environments, preventing humidity-induced haze.

2. End-to-End Protection for Optoelectronic Materials

Beyond BLU, our films serve:

1). Mobile Covers:

– Anti-static films prevent micro-cracks on hardened glass during CNC machining.

2). Touch Panel Modules:

– Low-residue adhesive films avoid OCA contamination in lamination processes.

3). Optical Sheet/Plate Logistics:

– Custom thickness (50-200μm) films provide shock absorption for global shipping.

3. Technical Advantages of Professional PE Films

– Precision Adhesion Control: 5-50g/25mm tack range, residue-free removal.

– Functional Upgrades: UV-resistant, anti-fog, or conductive layers for specialized needs.

– Environmental compliance: Complies with RoHS/REACH standards and supports customization of biodegradable materials.

Conclusion

As experts in PE protective film solutions for the optoelectronic industry, we are committed to reducing customer production costs and improving product yield through customized protective solutions. If you need to obtain the exclusive protective film test report and technical parameters for BLU/optical materials, please contact our engineering team.