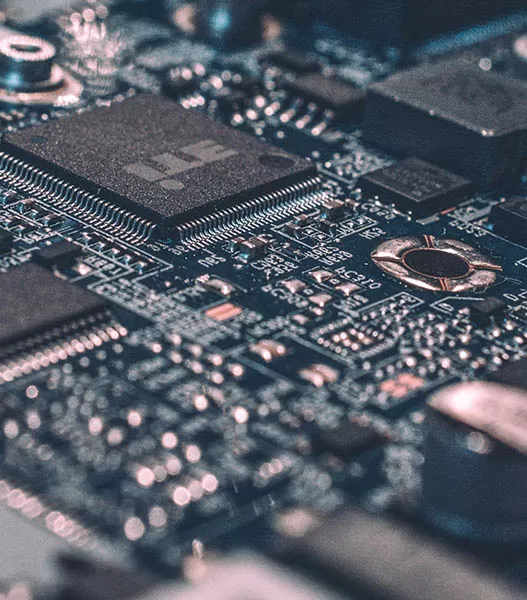

The electronic protective films, we mainly refer to temporary surface protective films used in the manufacturing process of electronic components. The main applications are glass-based display screens, such as touch panels, LED displayer, mobilephone screens, as well as plastic optical sheets, light guide plates, PC sheets, PMMA boards, etc. At the same time, we also have specialized products for certain electronic components that need to withstand high temperatures or anti-static required.

We have 4 film substrates to meet the surface protection needs of different application scenarios, including premium electronic protective film.

PE protective film

PET protective film

CPP protective film

Co-extruded self-adhesive protective film

Tape slitting, releasing lamination and die-cutting services are available upon request for protective film electronics.

Donlee protective film is mainly used to protect the shell of the product, metal/plastic frame, glass back panel, screen, battery cover, etc., in the metal (such as aluminum alloy, stainless steel) or plastic parts after being cut and polished by CNC, in the whole process of anodizing, spraying, electroplating, silk screen printing and other surface treatment, Donlee protective film is used, it can play the role of selective protective film, so that in the local surface treatment, protect the area that does not need to be processed.

At the same time, Donlee protective film also provides full protection for each workpiece during turnover and storage between processes, preventing scratches, bumps or fingerprints on the finished high-gloss surface. Once the product is assembled and ready to be delivered to the consumer, this temporary surface protection film is removed to reveal a flawless surface.

Donlee is a customized factory for on-demand production, after fully understanding the customer's use conditions, applying expectations and completing product matching, we will provide surface protection solutions accordingly to meet protective film needs of customers.