Here is the revised content. I have corrected the grammatical issues to improve the Trustworthiness and professionalism (a key E-E-A-T metric) of the text, while naturally integrating your new target keywords alongside the original SEO terms.

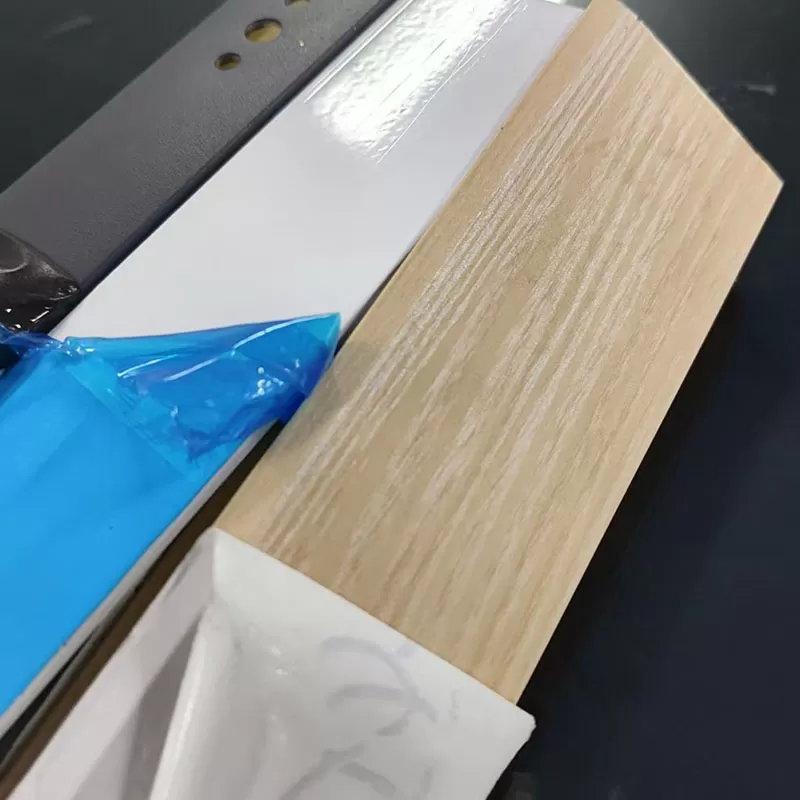

The surfaces of the aluminum panel or sheet are not immune to damage and wear, especially during the fabrication and finishing processes. Aluminum surfaces can be marred by chatter marks, scratches, swirls, or contamination. To prevent this, our premium protective film for aluminum and aluminum composite panel protective film (Tape) provides a temporary barrier that can absorb scratches or scrapes and block any liquid or solid contaminants. This thin, disposable film can be quickly peeled off upon delivery to the next stage of manufacturing or by the end customers themselves. We carry protective films to cover almost any type of natural, coated, and other treated aluminum finishes, all delivered to you in the size and shape that will best suit your needs.

Similarly, for extruded profiles, our protection tape for aluminium shares the same critical purpose: to protect the aluminum profile from damage, chatter marks, scratches, swirls, or contamination during transportation, inventory, processing, and installation. After completing the installation, the film can be removed easily without leaving any residue, leaving profiles looking brand new. These films feature outdoor endurance properties and can be printed with custom logo marks.

More Information

Donlee provides mainstream protective films for popular aluminum surface treatments such as anodized and powder coating. We also own product ranges for those “tough” finishes, such as sandblasted or laminated surfaces; we have super soft and specially formulated tapes to fit them. This includes our specialized aluminum sheet protective film, available as either acrylic-based or rubber-based, all set to be competent in the most demanding protective applications.

| Some brief data | |

| Film structure | Polyethylene film coated with Acrylic/Rubber PSA. |

| Colors | Clear, Blue, White, Black and White or optional |

| Thickness | 40mic~100mic |

| Width | 25mm~2600mm |

| Length | 200~1500M |

| UV-resistance | Max. 6 months |

| Logo printing | 2 colors |

| Packaging | telescope preventive packaging |

High-performance aluminum protective films might appear simple at first glance, but their design involves advanced engineering to meet the unique challenges of aluminum surfaces.

The Backing Layer: Typically made from Polyethylene (PE), this layer is durable yet flexible enough to conform to the contours of various profiles or sheets.

The Adhesive: Two main types dominate the market—Water-based Acrylic and Rubber-based Solvent.

Water-based Acrylic Adhesives: Eco-friendly and stable, ideal for smooth surfaces like anodized or powder-coated finishes.

Rubber-based Adhesives: Stickier with a stronger bond, making them suitable for rough or non-uniform surfaces, such as mill finish aluminum.

Choosing the wrong adhesive can lead to peeling, incomplete coverage, or dreaded adhesive residue. Understanding the interplay between surface finish, adhesive type, and intended use is the first step toward selecting the perfect product.

Aluminum applications come in all shapes and sizes, and so do their protection needs. Let’s break down the best practices for different scenarios.

For large, flat surfaces like Aluminum Composite Panels (ACPs) or mirror-finished sheets, maintaining pristine quality across wide surface areas requires attention to detail.

The Challenge: Bubble formation during application—common during the handling of wide sheets—can disrupt surface coverage.

The Solution: Opt for films featuring air-release technology, which minimizes trapped air for flawless application and adds long-term stability during storage and transit.

Pro Tip: For mirror-finished surfaces, prioritize protective films with lower adhesion to prevent distortion or ghosting upon removal.

Protecting narrow profiles like window frames, door profiles, and aluminum strips poses a unique challenge. These items often undergo machining or sawing with the protective tape in place, so the product must remain adhered under stress.

The Challenge: Insufficient adhesion can cause the film to peel during cutting, while overly sticky adhesives may leave residue.

The Solution: For such dynamic applications, choose protection tape for aluminium with higher adhesion and reinforced tensile strength to endure cutting and bending operations.

Pro Tip: European and Asian markets often refer to these as "protection tapes for aluminium" (with the international spelling). When sourcing internationally, ensure your supplier provides UV-tested options for outdoor exposure.

Choosing your anodized aluminum's toughest defender isn't one-size-fits-all. Let's evaluate three key considerations that will ensure optimal results:

Surface finishes demand varying adhesion levels:

Anodized or Mirror-finish: Go for low-adhesion films to avoid damaging the surface gloss or leaving ghosting.

Powder-coated or Sandblasted: Requires higher adhesion to adhere through uneven textures.

Selecting the wrong film for outdoor use can be disastrous. Many indoor-rated films break down under prolonged UV exposure, leaving behind sticky residue and impacting the aluminum's finish. For outdoor installations, ensure your film is rated for extended UV durability.

Applications involving bending, stamping, or deep drawing require films with high elongation properties. Look for films designed to stretch without tearing under mechanical stress.

Even the best protective film for aluminum won't perform as it should if applied incorrectly. Here's how to get it right:

Preparation: Ensure that the aluminum surface is thoroughly clean, dry, and free of oils or particulates.

Application: Flatten the film as you go to prevent air bubbles. For sheets, use a roller for even application over the surface.

Storage: Store aluminum with protection in a cool, dry place, away from prolonged sunlight or heat.

Removal: If residue is present after long-term storage, use a heat gun or solvent designed for adhesive removal.

Q: How long can I leave protective film on aluminum?

A: Most protective films are rated for 6–12 months of use, depending on environmental conditions like UV exposure.

Q: Why does protective tape leave residue on aluminum?

A: Residue typically occurs when low-quality adhesives are subjected to excessive heat, sunlight, or remain applied beyond their recommended lifespan.

Donlee is professional in know-how. We have been immersed in the line for 3decades and grounded in the largest manufacturing nation-land, thoroughly understand well client’ various needs for advanced protective film for aluminum and reliable protection tape for aluminium.

Donlee is massive in capability: we could move shipment fast in 3-30days from Donlee Premises. Thanks to the advantageous scale effect, cost competitiveness is realized meanwhile direct agreements with raw materials branded manufacturing suppliers are strategically reached and reliable protection tape for aluminium.

Donlee is responsible for Quality: for quality or spec discrepancies happened, which proved to be only caused by our reason, we shall assume our responsibility for them by practical compensation, even though such cases happen few in history, a commitment that underscores the reliability of our protective film for aluminum.

Our headquarter is located in Foshan China, and branch offices in Shenzhen, India, and Vietnam.

Our headquarters and major production base are located in Foshan China, 1.5hour driving from Hong Kong, affiliate companies exist in Shenzhen China, Suzhou China, Bac Ninh Vietnam, and UP Noida, India.

Please consult our sales staff with your specific film requirements, such as for aluminum sheet protective film. The protective film is a kind of technical product, its successful performance is subjected to substrate surfaces, applicable methods, processing steps, circumstances, etc. Knowing these details would help us greatly to recommend proper items. Nevertheless, the most reliable way is analyzing and testing samples of the substrate to be protected in Donlee lab, we'd match our product with great assurance for the client's satisfactory use.

Upon specific requirements and rather potential, it is our pleasure to provide free samples weighted within 1kg and use FedEx, DHL, or UPS to deliver them. The sample requested beyond 1kg is expected to be afforded by the consignee or negotiable.

MOQ is flexible. Usually, we propose 20000sqm and up, but for some special cases, we require a lower or higher amount.

Regular items delivery from warehouse: 2-3days

Converting product: 3-7days

Customized product: 7-30days

This is the most basic yet important procedure before we put the products on the market. As an ISO9001 certified company, quality is our life.