The Donlee EV battery tape series provides industry-leading, premium battery tape solutions engineered to meet the rigorous safety and performance demands of modern energy storage. Our comprehensive product line is primarily manufactured using high-performance functional base films such as PET, PI, and BOPP. These substrates are coated with specialized, high-stability pressure-sensitive adhesives via precision coating machinery to ensure long-term reliability in chemically sensitive environments.

Recognizing the diversity of energy applications, our products—including specialized battery terminal tape and high-dielectric battery insulation tape—can be fully customized in thickness, color, and adhesion levels to suit specific industrial scenarios. As a dedicated partner to the global battery industry, we provide a wide range of mission-critical solutions:

Terminal and Bonding: High-strength battery terminal tape for secure fixing and electrical connection protection.

Thermal Management: Temperature-resistant and fireproof tapes designed for extreme environments.

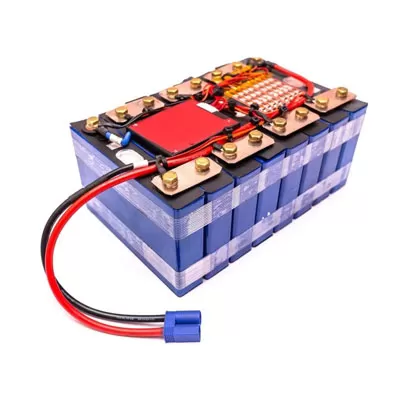

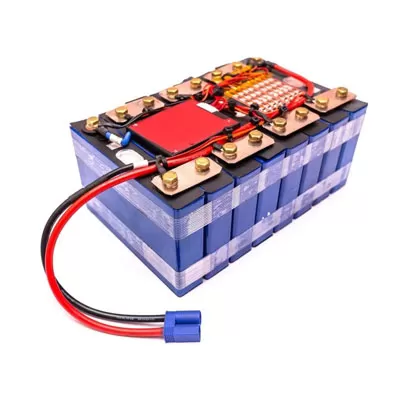

Electric Mobility: Specialized EV battery tape for battery pack wrapping, providing the mechanical strength and insulation required for automotive-grade reliability.

Donlee products are widely applied across the lithium battery manufacturing lifecycle. From terminal fixing and battery tab protection to aluminum case wrapping, our tapes ensure structural integrity. Furthermore, our battery insulation tape plays a critical role in safety and performance, offering essential temporary protection for pouch cells during in-plant processing. By constantly developing new, innovative battery tape technologies, Donlee remains at the forefront of battery safety and efficiency.

The terminal tapes are made of insulative PET film as substrate and coated with electrolyte-resistant acrylic adhesive specially formulated for lithium battery.

They are designed for fixing and insulative protection of positive and negative electrodes and other parts of lithium batteries. It‘s electrolyte resistance, high adhesion, soft easy and flat to apply. The materials are environmentally green and halogen-free.

The Dynamic Battery Tapes are made of blue dual-layer PET film as substrate, coated with high tack acylic pressure sensitive adhesive. Usually used for wrapping and packing rectangular aluminium cased dynamic power batteries.

Excellent alkali resistance, high tensile strength and fewest deformation rate. They own high performance features in stable self-adhesion, reliable insulation and thermal conductivity, also high temperature resistance, etc.

The Pouch Cell Process Protective Tapes are made of PET/PP as substrates, coated with flexible acrylic adhesive. They are specially designed to protect aluminum-plastic compositive foil- a component of the pouch cell-during the cell’s forming processes.

The tapes have no wrinkles happening after forming completion, no residue under high temperature and pressure, also free from ink transfer or fragments of printed codes.

The Battery Tab Tapes are made of PI (Polyimide) film as the substrates, coated with Electrolyte resistant pressure-sensitive adhesive. Specially designed for tabs protection when they are in steel and aluminum cased batteries, pouch cell, and cylindrical batteries.

The tapes wrap around ultrasonic welded Joints of the tabs to prevent puncturing that avoids short circuits from the battery core.

The tapes are high temperature and electrolyte corrosion resistance and prevent battery or cell’s internal resistance from abnormal raising.

| Item No. | Substrate | Adhesive | Total Thickness (Microns) | Peeling Strength (N/25mm) | Description | Application |

| LA30D-800CL | PET blue | Acrylic | 30±2 | ≥4 | Excellent electrolyte resistance, high adhesion, soft, flat, and easy to apply | For lithium batteries cores and terminals strapping fixation. |

| LA30G-700CL | PET green | Acrylic | 30±2 | ≥5 | ||

| LA75D-1200Z | PET | Acrylic | 105±6 | 12±3 | Using None-silicone PET substrates, a dual-layer structure | For insulative protection of aluminum cased batteries, provide an explosion-proof and impermeability barrier |

| DL70-15APE | BOPP | Acrylic | 72±4 | 0.22±0.05 | Good initial adhesion performance with firm holding, and excellent thermal stability. | For pouch cell process protection. No wrinkles after cells formed, no residues under high temperature and pressure, no cause ink transfer and fragments of printed codes. |

| IA25Y-500L | PI | Acrylic | 50±4 | ≥5 | Excellent mechanical properties, electrical insulation, and electrolyte resistance performance | For insulation protection of external electrode taps and circuits, also for batteries components bonding, assembling, sealing, and strapping. |

| TA25G-800CL | PET | Acrylic | 53±5 | 8±2 | Excellent High- temperature resistance, electric insulation, flame retardant performance. | For bonding cylindrical batteries blue, black and red plastic gaskets, using in the packing step of various cells and batteries. |